Plastic – Tap fittings

|

Title |

DETERMINATION OF THE SOURCE OF A SMELL |

|

Date |

2013 |

|

Objective |

To determine the source of a bad smell from a tap fitting |

|

Testing Undertaken |

Polymer insert in tap assembly tested by IR spectroscopy O ring, circlip and insert in tap assembly tested by SPME GC-MS |

|

Conclusion |

The IR spec matched that of Noryl. Result of SPME GC-MS was that most abundant compound was: Pentanoic acid, 2,2,4-trimethyl-3-carboxyisopropyl, isobutyl ester |

Plastic coating on aluminium – Panels

|

Title |

INVESTIGATION OF ADHESION FAILURE OF COATING TO ALUMINIUM PANELS |

|

Date |

2013 |

|

Objective |

To investigate the origin of adhesion failure of an organic coating on a surface treated aluminium sheet. |

|

Testing Undertaken |

ToF-SIMS analysis Surface topography by SEM |

|

Failure Mode |

The sample M exhibiting poor coating adhesion had high magnesium levels (2500 counts) and calcium levels (12000) counts (i.e. relatively high levels of hard water residues). The samples M and B exhibiting good adhesion had low magnesium levels (400; 100 counts) and very low calcium levels (200-500 counts). This suggested a strong correlation between magnesium and calcium deposits on the aluminium surface and the degree of coating adhesion. SEM revealed that sample M and B had a similar degree of surface pitting. Pit types observed: narrow deep, elliptical, wide shallow, subsurface and undercutting pits. |

Polyvinyl chloride (PVC) – Fabrics

|

Title |

PLASTICISER CONTENT OF A FABRIC SAMPLE |

|

Date |

2013 |

|

Objective |

To measure the plasticiser properties of a sample of PVC fabric samples |

|

Testing Undertaken |

PVC extracted using diethyl ether. Resultant ether solution heated until ether evaporated, mass of residue measured and percentage residue calculated. |

|

Conclusion |

PVC fabric using a polymeric plasticiser would have a much longer service life than a PVC fabric having a normal long chain ester plasticiser. |

Polyacetal – Plastic nuts

|

Title |

IDENTIFICATION OF FRACTURED PLASTIC NUT COMPONENTS |

|

Date |

2012 |

|

Objective |

To identify the composition of fractured plastic nut components with a view to determining the cause of the failure. |

|

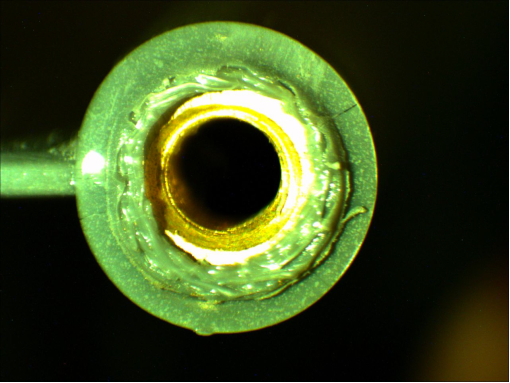

Photo |

Figure 1. Fracture surface of plastic nut |

|

Testing Undertaken |

FTIR by horizontal attenuated |

|

Failure Analysis |

The fractures samples were composed of Polyacetal (POM). Failure was possibly due to the parts undergoing oxidative stress cracking brought about by UV exposure. However, the parts were also exposed to hot water and it is very likely that the parts had degraded by hydrolysis which created formic acid and catalysed further hydrolysis, leading to degradation and embrittlement. |

Polybutylene – Water pipes

|

Title |

FAILURE ANALYSIS OF POLYBUTYLENE WATER PIPE |

|

Date |

2012 |

|

Objective |

To investigate the cause of failure of a sample of polybutylene water pipe |

|

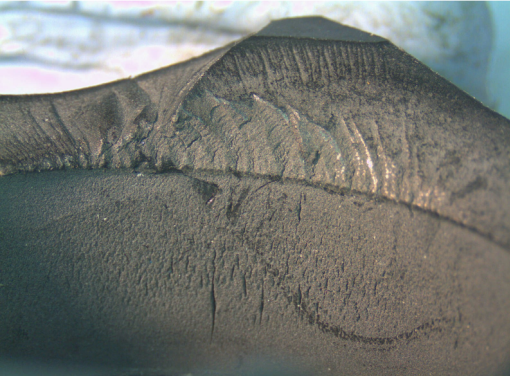

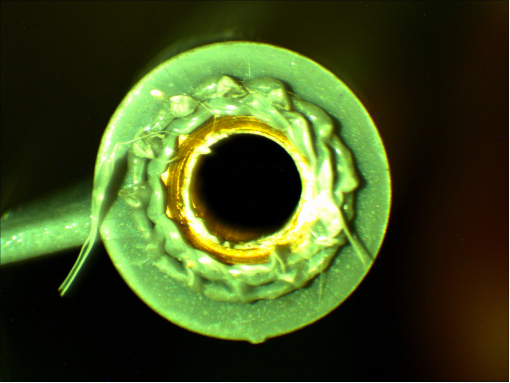

Photo |

Figure 1. Failure site – ductile/brittle failure. Note scuff marks near failure |

|

Testing Undertaken |

Failure analysis Wall thickness analysis |

|

Failure Analysis |

The pipe failed prematurely by ductile failure (Stage 1 failure), most likely due to over pressurization by operating pressure excursion. There is also some evidence of brittle failure, thus the failure is best characterized as ductile-brittle hybrid failure |

Polycarbonate – Injection mouldings

|

Title |

FAILURE ANALYSIS OF CRACKED MOULDINGS |

|

Date |

2013 |

|

Objective |

To investigate the origin of cracking of a polycarbonate injection moulded top cover for a mine application. |

|

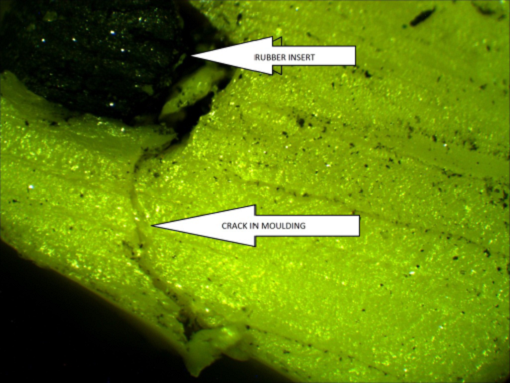

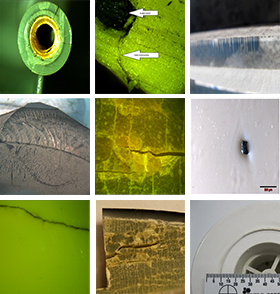

Photo |

Figure 1. Crack in top cover

Figure 2. Close up of cracking in top cover. Multiple crack fronts visible

Figure 3. Cross section of crack in top cover. Cracking seen to initiate at root of groove where o-ring is

Figure 4. Cracking position in side wall (originating at groove for rubber insert) |

|

Testing Undertaken |

Photomicroscopy Solvent Extraction IR spectroscopy |

|

Failure Mode |

Brittle nature of cracks and appearance of multiple crack junctions was indicative of environmental stress cracking. The cracking was traced back to the presence of the rubber insert. The rubber insert was chemically analysed and found to be made of an oil-extended styrene-co-isoprene synthetic rubber. The oil extender in the rubber appears to be a strong stress cracking agent for polycarbonate. |

Polycarbonate – Mouldings (1 of 2)

|

Title |

FAILURE ANALYSIS OF INJECTION MOULDED POLYMER CASES |

|

Date |

2013 |

|

Objective |

To identify the cause of hairline cracks in polycarbonate mouldings. |

|

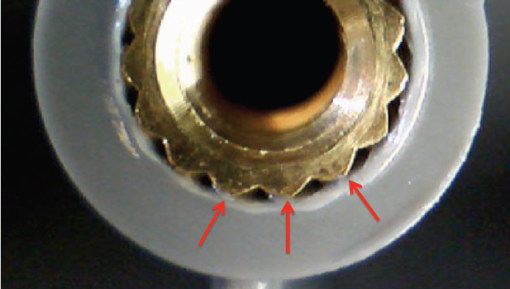

Photo |

Figure 1. Failure mode of polycarbonate mouldings

Figure 2. Star boss design creates stress concentrations |

|

Testing Undertaken |

IR analysis Failure analysis |

|

Failure Analysis |

The hairline cracks in the polycarbonate mouldings were due to: stress cracks from shrinkage around the metal inserts, and oily residue on brass inserts which promoted stress cracking. |

Polycarbonate – Mouldings (2 of 2)

|

Title |

STRESS ANALYSIS OF INJECTION MOULDED POLYCARBONATE CASES |

|

Date |

2013 |

|

Objective |

To test a number of polycarbonate moulded 10.4-inch cases that have been subjected to different treatments to advise the best treatment strategy in order to minimise boss cracking around the threaded metal inserts |

|

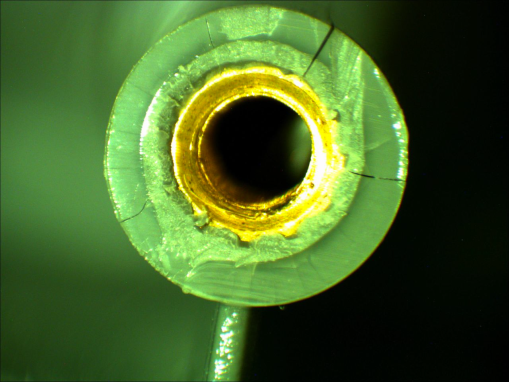

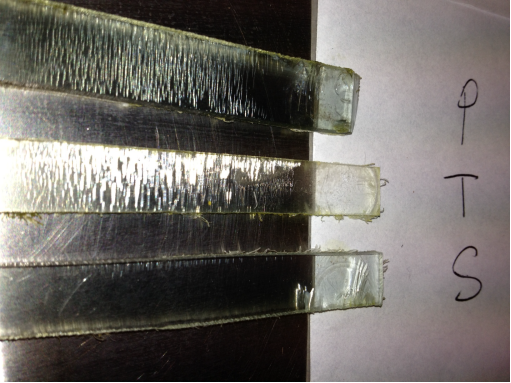

Photo |

Figure 1. Moulding 1 after immersion

Figure 2. Moulding 2 after immersion

Figure 3. Moulding 3 after immersion |

|

Testing Undertaken |

Stress tested by immersion in a 50/50 vol./vol. methanol/ethyl acetate blend for 3 minutes as per GE Plastics Testing Procedure. Then examined for the presence of stress cracking and number of cracks recorded using travelling digital microscope |

|

Conclusion |

The moulded-in stresses in all cases in the area directly around the metal inserts were greater than 500 psi. |

Polycarbonate; Polyether sulfone (PES) –

Mouldings

|

Title |

IDENTIFICATION OF UNKNOWN POLYMER SAMPLES AND CAUSE OF FAILURE |

|

Date |

2013 |

|

Objective |

To determine the identity of an unknown polymer sample, and determine the cause of failure. |

|

Photo |

Figure 1. Photograph of handle and switch plate

Figure 2. Photograph of handle showing multiple crack fronts initiated from a sharp moulded in notch at the point where the gripping teeth are present |

|

Testing Undertaken |

FT-IR (per ASTM E573) DSC (per ASTM D 3418) |

|

Failure Analysis |

Handle: The handle material was Poly(ethersulfone) (PES). The nature of the cracking on the handle was highly suggestive of stress cracking as the material was locally embrittled and there were multiple crack fronts (see Figure 2). It was likely that the handle had been in contact with a disinfectant or cleaning chemical based on some organic chemicals (such as ketones, esters, DMSO, aromatic amines, nitrobenzene and some chlorinated hydrocarbons)

Switch plate: The switch plate material was most likely polycarbonate (PC). The failure was also due to stress cracking and may have been due to the same type of chemicals that affected the PES handle. |

Polycarbonate; SAN; Tritan – Appliances

|

Title |

STRESS CRACKING RESISTANCE OF AMORPHOUS POLYMERS |

|

Date |

2013 |

|

Objective |

To investigate the sensitivity of various clear amorphous polymers to stress cracking in the presence of d-limonene, orange oil and lime oil. The polymers were from fruit juice extractor components |

|

Photo |

Figure 1. Results of Moderate Strain Test (dia. 400 mm). Note crazing on all three samples

Figure 2. Results of Low Strain Test (dia. 600 mm). Note that SAN has not yet crazed. |

|

Testing Undertaken |

ISO 22088-2:2006 Plastics – Determination of resistance to environmental stress cracking (ESC) – Part 3 Bent Strip Test. The following three citrus essential oils components were used as stress cracking agents: D-limonene, orange oil and lime oil. |

|

Conclusion |

All three polymers (PC, SAN and Tritan™) underwent crazing and stress cracking under high and moderate strain. In the low strain test only SAN was most resistant followed by PC and then Tritan™. Tritan underwent stress cracking the quickest in all tests with all media tested. |

Polycarbonate; Tritan – Appliances

|

Title |

IZOD IMPACT STRENGTH MEASUREMENT OF POLYMER SAMPLES |

|

Date |

2013 |

|

Objective |

To measure the izod impact strength of polymer samples |

|

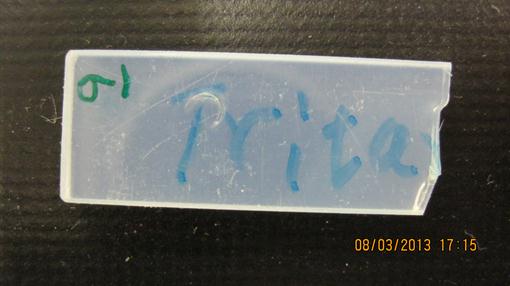

Photo |

Figure 1. Tritan specimen showing translucent effect after immersion in d limonene. No damage from notching apparatus

Figure 2. Polycarbonate specimen showing effect of immersion in d-limonene. Evidence of severe stress cracking at points where specimen held in notching apparatus.

Figure 3. Stress cracking of Polycarbonate specimen after immersion in d limonene |

|

Testing Undertaken |

Izod Impact Strength measurement testing according to ASTM D 256 using Test Method A |

|

Conclusion |

D limonene can cause stress cracking of polycarbonate. |