Polypropylene – Caravan hatches

|

Title |

ANALYSIS AND TESTING OF CARAVAN HATCHES |

|

Date |

2013 |

|

Objective |

To determine whether the parts are ‘fit for purpose’ |

|

Photos |

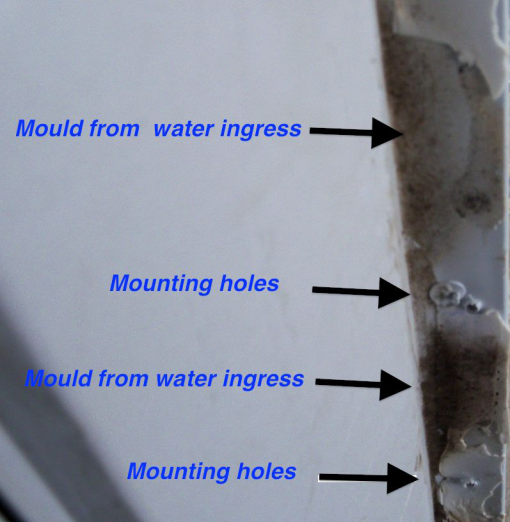

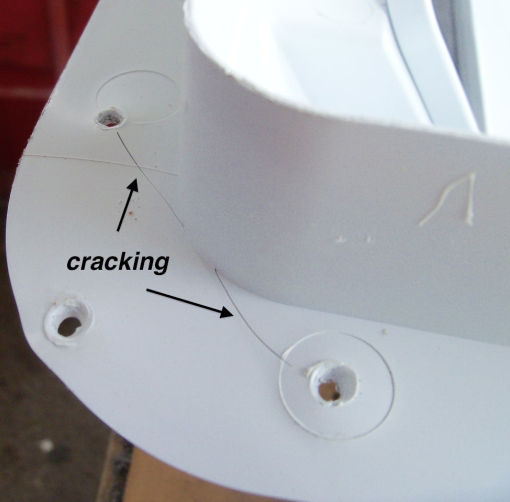

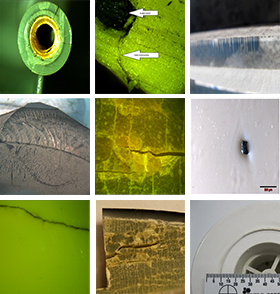

Figure 1. Pathways for water ingress

Figure 2. Photograph of cracking between screw holes. |

|

Testing Undertaken |

Thermal analysis according to ASTM D 3417 Heat of Fusion Crystallization Melting Point Glass Transition Filler Content Analysis according to ASTM D256 – 10 Standard Test Methods for Determining the Izod Pendulum Resistance of Plastics on notched specimens Tensile strength and elongation according to ASTM D638 – 10 Surface energy according to ASTM D2578 – 09 Antioxidant levels according to ASTM D3895 UV stabiliser levels according to ASTM D5885 – 06(2012) |

|

Conclusion |

The parts installed by either method were not ‘fit for purpose’ due to their modest physical properties, low surface energy and tendency to bow and distort (due to high flexibility and thin walled flange design). The testing demonstrated: · The parts were made from homopolymer PP (lower toughness and lower ductility than copolymer PP). · The parts contained ~ 10% talc filler (can provide reinforcement, decreased mould shrinkage, and increased modulus to PP, however, can also lead to decreased ductility of the PP and increased brittleness). · Poor mechanical properties such as low impact strength (37 J/m) and low elongation (3%) and are prone to crack initiation and propagation. · Tensile strength at yield was 29 MPa and elongation at yield only 3%, indicating talc filler had adversely affected PP ductility. · A low surface energy was measured (~30, consistent with that of untreated PP), indicating the hatches could not be glued with any commercial adhesives. · The parts had a high degree of thermal expansion compared with aluminium and hence PP has inferior dimensional stability with temperature changes It was thus recommended that the preferred material for this application (to resist distortion from thermal expansion) is powder coated aluminium or the specified engineering polymer, as both have good mechanical properties, are fairly rigid and resistant to bowing, are easy to adhere and are UV stable. |

Polypropylene – Furniture

|

Title |

MOULDED CHAIR SHELLS |

|

Date |

2011 |

|

Objective |

To analyse the composition of two moulded chair shells and to investigate why the matt chair is splitting along the weld line. |

|

Photo |

Figure 1a and 1b. Photograph of the split section of the seat shell |

|

Testing Undertaken |

IR-Spec DSC |

|

Failure Analysis |

Overmoulded over a metal frame and the shrinkage of the polymer led to stresses that caused fracture along the weld line. |

Polypropylene – Liners

|

Title |

FT-IR ANALYSIS OF A POLYPROPYLENE LINER |

|

Date |

2013 |

|

Objective |

To determine if there are any signs of chemical attack or traces of residual chemicals on a polypropylene liner sample |

|

Photo |

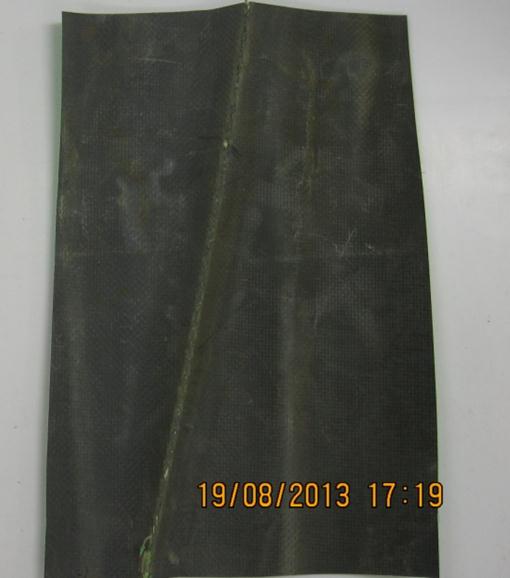

Figure 1. Sample (used PP liner)

Figure 2. Markings on reverse side of sample indicating it had been folded |

|

Testing Undertaken |

FT-IR analysis according to ASTM E 573 |

|

Failure Mode |

No spectral evidence was found of chlorination in the used PP liner; however, there was evidence of oxidation with a significant carbonyl index. Markings on the green side of the used sample indicate it had been folded (Figure 2), which could have induced stress and led to cracking, with or without a reagent present |

Polypropylene – Plastic nuts

|

Title |

ANALYSIS OF POLYMER COMPONENT |

|

Date |

2013 |

|

Objective |

To determine if the polymer sample has undergone oxidation. |

|

Photo |

Figure 1. Fractured plastic nut. Marked area indicates where S-OIT and IR samples were taken from |

|

Testing Undertaken |

S-OIT FTIR |

|

Failure Analysis |

Fractured surface of nut showed evidence of oxidation (which was not seen in the unaffected surface). |

Polypropylene (PPR) – Water pipes (1 of 3)

|

Title |

FAILURE ANALYSIS OF GREEN PP-R HOT WATER PIPING |

|

Date |

2013 |

|

Objective |

To investigate the root cause |

|

Photo |

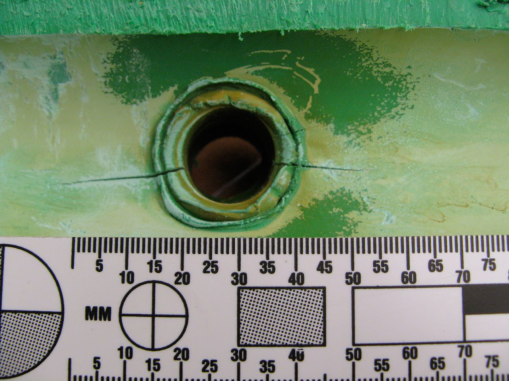

Figure 1. Sample ‘Leak 1’

Figure 2. Sample ‘Leak 2’

Figure 3. Areas circled in red analysed by elemental analysis |

|

Testing Undertaken |

Optical Microscopy ATR-IR Surface Spectroscopy SEM & Elemental Analysis Oxidative Induction Time according to ASTM D3895 using DSC |

|

Failure Mode |

Failure was due to oxidative stress cracking (OSC) which is oxidation accelerated by the presence of stress. The inside bore of both samples had very low OIT values consistent with full depletion of antioxidant reserves, meaning the polypropylene was unprotected against oxidation. The ‘Flexi-strut’ style steel channel clamp used to clamp the PP-R pipes lacked the rubber cushion inserts and this led to the application of damaging localised stresseson the PP-R pipe. Elemental analysis revealed heavily crazed and cracked bore surface, heavily oxidised polymer surface and copper ions. |

Polypropylene (PPR) – Water pipes (2 of 3)

|

Title |

FAILURE ANALYSIS OF PP-R WATER PIPES |

|

Date |

2013 |

|

Objective |

To investigate the cause of failure of PP-R pipes |

|

Photo |

Figure 1. Water pipe samples

Figures 2 and 3. Cracking in samples |

|

Testing Undertaken |

Photomicroscopy Oxidative induction time testing per ASTM D-3895 Carbonyl Index by FT-IR Spectroscopy |

|

Failure Mode |

The residual stability of Sample 3 was 50% greater than Sample 2, while Sample 2 was 10x more stable than Sample 1. OIT results showed that the antioxidant/stabilizer levels in Sample 1 were completely depleted, which when combined with the presence of residual/applied stresses caused oxidative cracking. This cracking initiated on the inner surface of the saddles/fittings and propagated through the inner surface of the pipes. Thus LB01 was not fit for service for warm water under Australia conditions. |

Polypropylene (PPR) – Water pipes (3 of 3)

|

Title |

Cracking of Green Pipe |

|

Date |

2013 |

|

Objective |

Failure analysis |

|

Photo |

Figure 1. Extensive cracking observed in internal fitting in pipe sample 2. Note cracking has initiated in the fitting and propagated significantly into the pipe itself.

Figure 2. Photomicroscopy on the cracked internal welded-in fitting of Sample 2. Note highly oxidized chalky/powdery surface layer due to thermal oxidation of the PP-R.

Figure 3. Photomicroscopy on the cracked internal welded-in fitting of Sample 2. |

|

Testing Undertaken |

Photomicroscopy OIT (per ASTM D-3895) |

|

Failure Analysis |

The PP-R pipes were not ‘fit for purpose’ |

Polyurethane – Castings

|

Title |

UV TESTING OF POLYURETHANE |

|

Date |

2013 |

|

Objective |

To determine the effect of |

|

Photo |

Figure 1a. Sample Cast # 1.1 after removal from UV exposure.

Figure 1b. Sample Cast # 1.1 comparison of exposed and unexposed surfaces at x4 magnification. Significant change of colour although surface has not degraded to the point of chalking.

Figure 2a. Sample # 1.2 CAST after removal from UV exposure.

Figure 2b. Sample # 1.2 CAST comparison of exposed and unexposed surfaces at x4 magnification. Significant change of colour although surface has not degraded to the point of chalking. |

|

Testing Undertaken |

Exposure to UVA radiation per ASTM G154-12a, followed by visual inspection for changes in colour, cracking or chalking at x4 magnification |

Polyurethane – Flame retardants

|

Title |

IDENTIFICATION OF FLAME RETARDANTS IN POLYURETHANE SAMPLES |

|

Date |

2013 |

|

Objective |

To determine the presence and possible identity of flame retardants in two material samples |

|

Testing Undertaken |

FT-IR analysis according to ASTM E 573 Elemental analysis via EDAX |

|

Failure Mode |

High levels of chlorine in both samples pre- and post-ashing were an indicator that both materials most likely used chlorinated paraffin or a chlorinated wax as a flame retardant |

Polyurethane – Layflat hoses

|

Title |

CRACKED LAYFLAT HOSE |

|

Date |

2012 |

|

Objective |

To investigate the origin of cracking black layflat hose used in a pipeline bypass application. |

|

Photo |

Figure 1. Appearance of microcracking. Note parallel microcracking indicates oxidative stress cracking mechanism

Figure 2. Results of stress crack test on the black polyurethane layflat hose after immersion in 1% aq. chlorine |

|

Testing Undertaken |

IR-Spec Digital Microscopy Chlorine Exposure Testing |

|

Failure Analysis |

The hose failed due to oxidative stress cracking caused by chlorine exposure in the field. |