Polymer Testing have a broad range of analytical capabilities for the analysis and characterisation of polymeric materials and their additive systems. The main techniques employed are described below. Please contact Polymer Testing to discuss specific polymer analysis requirements

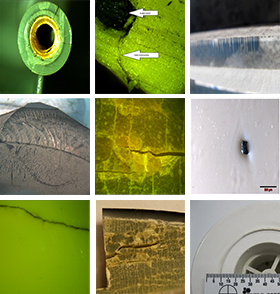

FTIR – Fourier Transform Infrared Spectroscopy is the workhorse tool for identifying and characterising polymer materials and their additives. Polymer Testing uses a Bruker Diamond ATR FTIR. Spectra from unknown polymers can be readily compared with our extensive reference spectral library. The ATR method is a powerful technique in problem solving – particularly for the identification of inclusions or defects in moulded parts or plastic films. The carbonyl index using FTIR can determine the extent of surface oxidation of polymers.

DSC – Differential Scanning Calorimetryis a thermal analysis technique that measures heat flow to of from a polymer. By monitoring the heat flow as a function of temperature phase transitions such as crystalline melt temperature (Tm), crystallisation temperaturee (Tc) and glass transition temperatures (Tg) can be measured. Using the crystallisation temperature and %crystallinity the thermal history of a sample can be gained. The DSC technique can also be used to determine the thermal stability of polymers and their residual antioxidant/stabilizer levels by determination of the OIT (oxidation induction time)

TGA – Thermogravimetric Analysis (TGA) measures changes in the weight of a sample as a function of increasing temperature. TGA is used to determine polymer degradation temperatures, absorbed moisture content, residual solvent levels and the amount of inorganic (non-combustible) filler in polymer or composite samples. It can also assist in deformulation of complex polymer products such as rubber goods.

Elemental Analysis Microscopy – EAM is a powerful surface imagining technique which uses x-rays to determine the elemental composition of small samples.