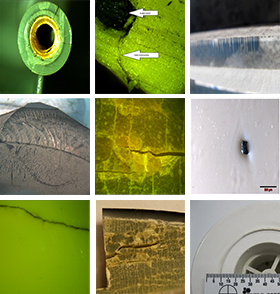

Determining the root cause of a plastic component failure is the first step towards implementing corrective action. Polymer Testing have extensive experience in polymer failure analysis of products manufactured from a wide range of plastic materials used in diverse service applications. The majority of plastic component failures occur in the mid to long term of the intended design life. Even normally tough and ductile plastic materials can fail in a brittle manner resulting in premature failure and in a short service life. Brittle failures are most commonly caused by:

incorrect material selection – the use of an incorrect polymer for a specific application is a common cause of polymer failure. For instance, lack of understanding of the interaction of polymers with chemicals and environments commonly leads to premature failure;

inappropriate design – proper product design is fundamental to ensure plastic components will have long term durability. Poor design in combination with long-term loading, high speed loading, chemical environments, cyclic (fatigue) loads can cause brittle failure of the product within a short service life;

processing errors – incorrect processing of plastic materials can lead to failure via degradation and embrittlement process, material inhomogeneity, high residual stresses, inclusion of moulding defects or contaminants;

chemical & environmental factors– interactions betweens polymers with chemicals and environments can lead to degradation of cracking of polymers. For many polymers specific interactions with common household products can lead to rapid crazing, cracking, fracture and product failure.